Understanding Gantry Crane Specification

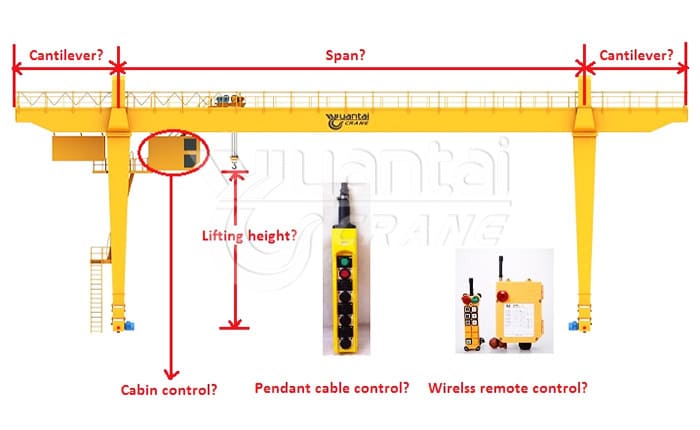

Gantry cranes, with their ability to lift and transport heavy loads, play a crucial role in various industries, including manufacturing, construction, and logistics. Understanding gantry crane parameters is essential for businesses looking to invest in an efficient and tailored material handling solution. Understanding and determining the following gantry crane Specification is the first step for you to purchase a gantry crane:

- Lifting Capacity:

The lifting capacity of a gantry crane is one of its most critical specifications. It refers to the maximum weight the crane can safely lift and transport. Gantry cranes come in a range of capacities, catering to diverse material handling needs. - Span:

The span of a gantry crane represents the horizontal distance between the two supporting legs of the crane. The span determines the coverage area of the crane within a workspace. Gantry cranes can have adjustable spans, allowing for customization based on the specific layout and requirements of the facility. The ability to tailor the span ensures optimal use of available space. - Lifting Height

The lifting height specification outlines how high a gantry crane can lift loads. This dimension is particularly important in applications where materials need to be stacked or placed at elevated levels. Gantry cranes are designed with variable lifting height options, accommodating the specific needs of different projects. The lifting height, in conjunction with the span, contributes to the crane’s versatility and adaptability to various operational scenarios. - Speed:

Speed is a dynamic specification that influences the efficiency of gantry crane operations. Gantry cranes have both vertical and horizontal movement speeds, and these metrics contribute to the overall productivity of the crane. The speed specifications are optimized for precise movements, allowing operators to lift, transport, and position loads with accuracy and efficiency. The ability to control the speed of the crane enhances safety and reduces the time required for material handling tasks.

If you want to inquire about a gantry crane from us, please provide at least the parameter information of the gantry crane. After receiving your inquiry, we will provide you with a free quotation as soon as possible:

- lifting capacity:____ ton

- lifting height:____ m

- span: ____m

- voltage: ____V ____HZ ____Phase(for example: 380V-50Hz-3Phase)

Gantry Crane Dimensions

Gantry crane dimensions go beyond just the lifting height and span. The adaptability of these cranes to various workspaces is a key factor in their design.

- Adjustable Span: The span of a gantry crane can often be customized to fit the width of the workspace. This ensures that the crane provides optimal coverage without unnecessary overhangs, maximizing efficiency and safety.

- Variable Height Options: Gantry cranes can be designed with variable lifting heights to accommodate specific stacking or placement needs within a facility. This adaptability allows for seamless integration into diverse operational environments.

Customization in dimensions ensures that the gantry crane aligns with the unique layout and requirements of the workspace, providing a tailored solution for efficient material handling.

Several Popular Gantry Crane Specifications

Gantry cranes come in various types and configurations to cater to different industries and material handling needs. Here, we will explore the parameters of several popular standard gantry cranes, providing insights into their capacities, spans, lifting weights, and other essential specifications.

- Single Girder Gantry Crane Specification:

- Capacity: 1~20t

- Span: 8~30m

- Control System: Pendant control or radio Remote Control

- Application: Ideal for workshops, warehouses, and maintenance operations

- Double Girder Gantry Crane Specification:

- Capacity: 5t~500t

- Span: 12~35m

- Control System: Cabin control or remote control

- Application: Suited for heavy manufacturing, steel yards, and shipbuilding

- Rubber Tyred Gantry Crane (RTG Crane) Specification:

- Capacity: 1~50t

- Span: 10-30m

- Control System: Cabin control with advanced automation features

- Application: Mainly used in container terminals and port operations

- Semi-Gantry Crane Specification:

- Capacity: 2~20t

- Span: 8~20m

- Control System: Pendant control or cabin control

- Application: Suited for outdoor construction sites and limited-space environments

- Portable Gantry Crane Specification:

- Capacity: 0.25-10t

- Span: 2-12m

- Control System: Portable pendant control

- Application: Ideal for temporary or mobile lifting needs in workshops and job sites

5 Ton Gantry Crane Specifications

- Lifting Capacity: 5 ton

- Span: 8m~30m

- Working Class: A3, A4

- Ambient Temperature: -20~40℃

- Pendant Control: Standard pendant control for ease of operation.

40 Ton Gantry Crane Specifications

- Lifting Capacity: 40 ton

- Span: 12m~35m

- Working Class: A5, A6

- Ambient Temperature: -20~40℃

- Cabin Control: Often equipped with cabin control for a better view and control of heavy loads.

Choosing the Right Gantry Crane

- Type of Material: The nature and weight of the materials being handled influence the required lifting capacity. Different industries may have varying material handling needs, and the gantry crane must align with those requirements.

- Workspace Constraints: The dimensions of the workspace, including available floor space and ceiling height, impact the choice of gantry crane dimensions. Customization becomes crucial to ensure an optimal fit within the operational environment.

- Operational Environment: Factors such as weather conditions, frequency of use, and operational hours play a role in determining the features and technology integration needed for a gantry crane. For example, cranes used in outdoor environments may require additional weatherproofing features.