Crane Hook Group Introduction

Crane hook group is one of the most widely used loads handling devices, which consists of hook, hook nut, thrust bearing, hook beams, pulley, pulley bearings, pulley hanger, etc. A Crane lifting hook is a common device for grabbing and lifting loads used by a hoist or crane. The lifting hook is usually equipped with a safety latch to ensure the wire rope sling, chain or rope is in the proper place of hook and ensure the safety. With one or more built-in pulleys, the crane hook group can amplify the lifting force.

Due to the characteristics of simple manufacture and strong usability, the crane hook group is used widely to handle materials. As the most widely used loads handling devices, crane hook groups are usually used with hoists, overhead cranes, gantry cranes or jib cranes for handling materials in various applications in different industries.

Due to the characteristics of simple manufacture and strong usability, the crane hook group is used widely to handle materials. As the most widely used loads handling devices, crane hook groups are usually used with hoist or crane machinery for handling materials in various applications in different industries.

Crane Hook Types&Crane Hook Block Types

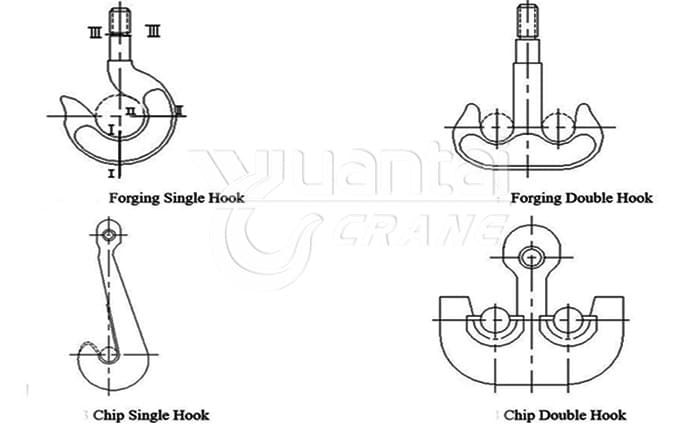

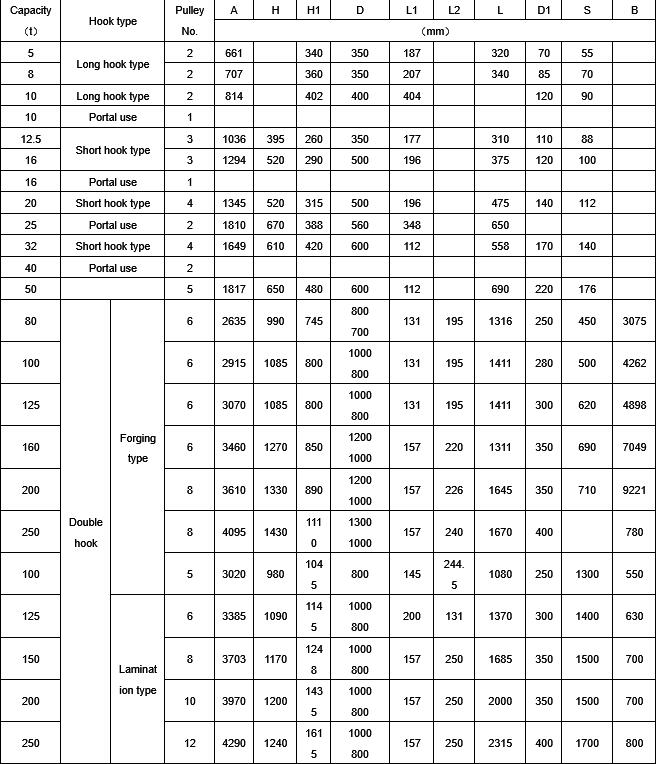

- According to shape, it can be classified into a single hook, double hook, C-type hook, etc. The advantage of the single hook: easy to make and use, and applied to light capacity. The load capacity of the double hook is better and widely used in heavy capacity.

- According to the production method, it can be classified into a forging hook and a chip hook (plate hook). A forging hook is widely used. Chip hook is a combination of steel plate and more safety than forging hook.

- According to the cross-section, it can be classified into roundness, squareness, trapezium, and T type. Among them the cross-section of the T type is the most reasonable, but complicated technology; the cross-section of the trapezium is less reasonable than the T type but with simple technology and is widely used. The squareness cross-section is often used in chip hooks, while the roundness cross-section is often used in simple light crane hooks.

- According to its mechanical capacity, it can be classified into M、P、(S)、T、(V) based on the yield point or yield strength of the material.

Crane Hook Material

The hook should have higher strength, plasticity and toughness. Widely adopt low-carbon steel and low-carbon alloy steel. For example, level M and P hook always adopt DG20Mn; level T, and M adopt DG34CrNiMo or DG30Cr2Ni2Mo. To avoid strain, adhesive and brittle, ISO suggests the minimum content of Al is 0.02%. The material of the hook can take GB10051.1 “Crane Hook” for reference.

Crane Hook Parts

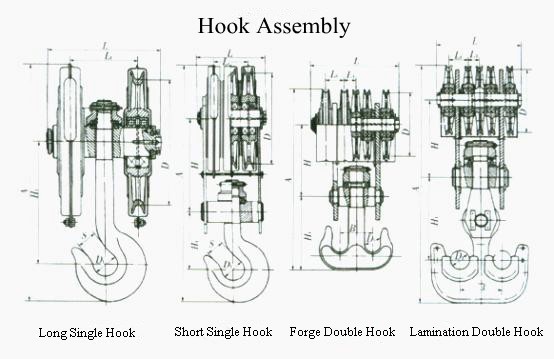

To increase the lifting capacity and reduce the demand for the wire rope’s diameter, will make the hook and pulley block into one. So this is called the hook group. The large lifting appliance always uses a hook group. The hook group is divided into a long hook group and a short hook group. When the balanced pulley is installed on the long hook group, the hook group with a singular rate has a larger lifting capacity. Short hook group applied to double rate one and has a smaller capacity.

A crane hook consists of several parts that work together to perform the lifting function. The main parts of a crane hook are:

- Hook Body: The hook body is the main part of the crane hook that holds the load. The hook body is usually made of high-strength steel or alloy steel that can withstand high stress and wear. The shape and size of the hook body depend on the type of crane hook and the load capacity.

- Hook Point: The hook point is the tip of the crane hook that grabs the load. The hook point can be sharp or blunt, depending on the type of load and the safety requirements. The hook point should be smooth and free of cracks or defects that may cause slippage or damage to the load.

- Hook Shank: The hook shank is the part of the crane hook that connects to the wire rope or chain. The hook shank can be straight or curved, depending on the type of crane hook and the angle of lifting. The hook shank should be strong enough to support the weight of the load and the tension of the wire rope or chain.

- Hook Nut: The hook nut is a device that secures the hook shank to the wire rope or chain. The hook nut can be fixed or adjustable, depending on the type of crane hook and the flexibility of operation. The hook nut should be tight enough to prevent loosening or detachment of the crane hook.

- Hook Latch: The hook latch is a device that prevents accidental release of the load from the crane hook. The hook latch can be manual or automatic, depending on the type of crane hook and the safety standards. The hook latch should be easy to operate and reliable in function.

- Hook Block: The hook block is a device that supports and guides the wire rope or chain through a pulley or sheave system. The hook block can have one or more pulleys or sheaves, depending on the type of crane and the lifting speed. The hook block should be compatible with the crane hook and the wire rope or chain.

Hook Group Inspection

Inspection requirement of forging hook

- The crack on the hook surface is not allowed, or else should be abandoned.

Inspection method: visual inspection or dye check with 20 times magnifying glass. For the 10 years used the hook, should be disassembly and inspection testing. For hook used in poor working conditions and frequency operation, should be inspected every 5 or 6 years. Focus on the inspection of the three dangerous cross-sections. - The hook is made from new materials based on the GB10051-88 “Crane Hook”, it should be scrapped when its mouth deformation reaches 10% of the original. For another hook, it should be scrapped when the mouth deformation reaches 15% of the original.

Inspection method: measured by vernier calliper. - Check the torsion deformation of the hook, and it should be scrapped when the torsion of the hook body is more than 10°.

Inspection method: measured by streak plate method. Place the hook on the platform using the vertical straight rule and adjust the electric block to find out the central line of the main hook body and the crossing point of the hook point’s central line and hook body. Then make a vertical line from the hook point to the central line of the hook body. Measure the distance between the foot point and the cross point, then calculate the angle. - The hook handle must not have plastic deformation, or else should be scrapped.

Inspection method: visual inspection or measured by vernier calliper. - Check the wearing capacity of the hook’s dangerous cross-section. It should be scrapped when the actual size is less than 90% of the original size (95% when the hook is made from the new material in GB10051-88 “Crane Hook” ).

Inspection method: measured by vernier calliper. - The hook screw should avoid corrosion phenomenon, or else should be finished and machined to get rid of corrosion detection. Should be replaced with a new nut when the axial clearance exceeds the allowable value.

Inspection method: visual inspection. The measured axial movement can be axial clearance if the axial clearance can move the nut. - After corrosion, the hook handle size should not be less than 90% (95% when the hook is made from the new material in GB10051-88 “Crane Hook”)of the original, or else should be scrapped.

Inspection method: vernier calliper or outside calliper. - Not allow repair welding for hook’s defect.

Inspection requirement of chip hook

- A surface crack exists on the hook and suspension hole. The hook piece’s existing surface crack must be replaced.

Inspection method: visual inspection or dye check with 20 times magnifying glass. - Check the lateral deformation value if it exists. When the bending radius of the deformation value is more than 20 times the thickness of the plate, the plate is by cold straightening. When the bending radius of the deformation value is 10-20 times the thickness of the plate, must do normalizing after cold straightening. When the bending radius of the deformation value is less than 10 times the thickness of the plate, must replace the hook piece.

Inspection method: place the chip hook on the platform, and use the height caliper and plate gauge to measure the chip hook side deformation height and the distance between the bending start point and the chip hook’s undersurface outlines. - The wear of the chip hook, suspend splint and dangerous cross-section of the screw should not be more than 50% of the original size. Also, the wear gap and defect must be rubbed off smoothly.

Inspection method: same as forging hook. - When the wear of the chip hook’s bushing block reaches 50% of its original size, it should be replaced.

Inspection method: measured by callipers. - Chip hook does not allow wear repair.

- When the wear of the chip hook mandril reaches 5% of the original size, it should be replaced.

- When the rivet on the chip hook is loose or broken, and the plate space is increased obviously or even exceeds the factory regulations, it should be replaced.

Inspection method: combining a visual inspection with a feeler gauge. - When the wear of the chip plate hook’s wear strip reaches 50% of its original size, it should be replaced.

Different Crane Hook Specification

By way of making, the hook can be classified into a forging hook and a chip hook. The forging hook is classified into single hook and double hook.

The single hook is usually applied to light capacity (max. capacity no more than 80 tons), and the double hook is often used in heavy capacity.

Chip hooks also can be classified into single hooks and double hooks.

During work, the hook is often affected by impact and load. So the material should have better toughness besides enough intensity. Forging material should adopt high-quality low-carbon killed steel or low-carbon alloy steel, such as 20 high-quality low-carbon steel, 16Mn, 20MnSi, 36MnSi, and annealing after the forge.

Chip hook is made of a hook sheet which is punching sheared by several 16Mn steel plates with a thick no less than 20mm and then riveted together.

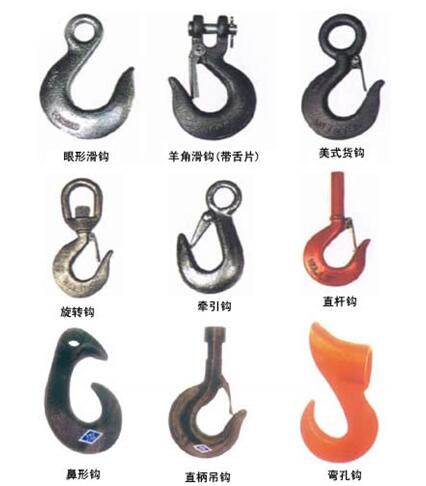

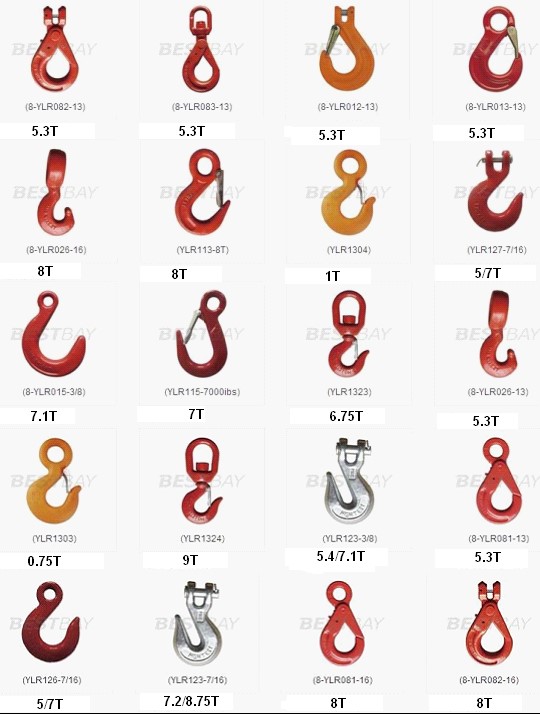

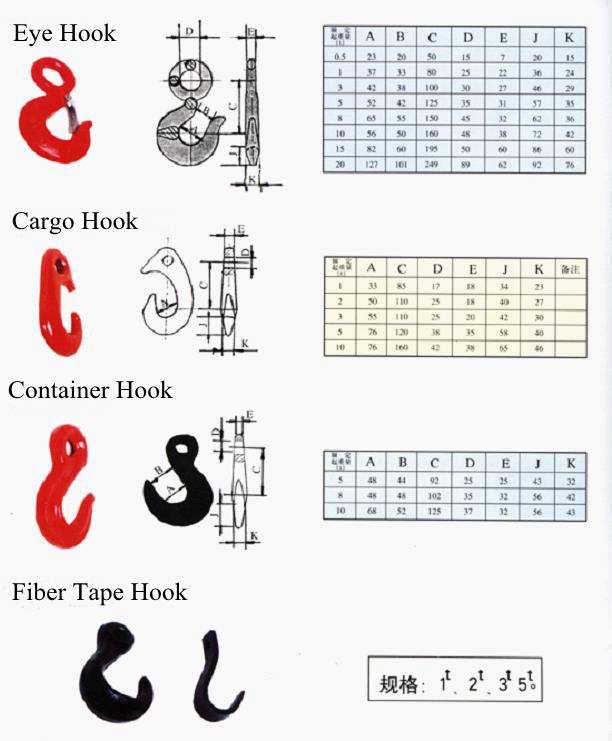

Eye safety hook, eye slide hook (with tongue or without tongue)

Horn safety hook, horn slide hook (with tongue or without hook)

American cargo hook, American rotating cargo hook, American eye slide hook, American eye cargo hook.

If you have any crane hook needs, please feel free to contact us.