European Gantry Crane Overview

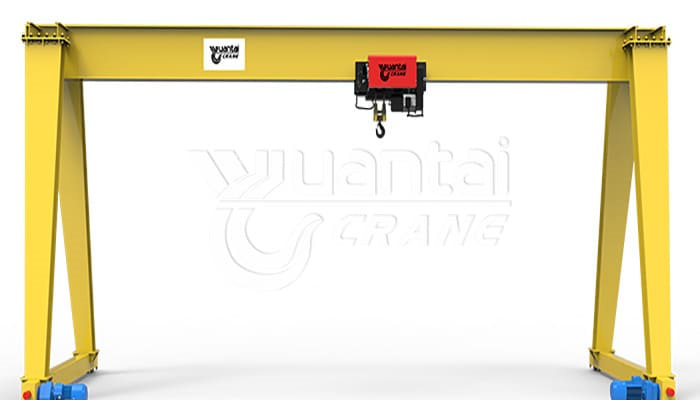

The European gantry crane complies with national standards and is equipped with a European Electric Hoist trolley. European gantry cranes are generally divided into European Single Girder Gantry Cranes and Double Girder Gantry Cranes, and their performance is better than standard gantry cranes. European single girder gantry cranes feature a single horizontal beam supporting the hoisting mechanism and feature a streamlined design and easy manoeuvrability, making them suitable for applications requiring medium lifting capacity. The European double girder gantry crane has two horizontal beams supporting the lifting mechanism, which has greater stability and lifting capacity and is suitable for heavier loads.

The new European hoist gantry crane is designed and manufactured according to Chinese crane standards and concerning the relevant standards of European cranes.

The crane is mainly composed of beams, outriggers, trolleys, electrical components, control rooms and other components. Standard lifting capacities are 3.2 tons, 5 tons, 8 tons, 10 tons, 12.5 tons, 16 tons, 20 tons, 25 tons, 32 tons, 50 tons, 63 tons and 80 tons. We can also customize the lifting capacity according to customer requirements. The span is from 7.5 m to 31.5 m. This hoist gantry crane has the characteristics of extreme safety, excellent design, ergonomics, and convenient and fast material handling. It is widely used in machinery manufacturing and assembly, warehouses and other places. It is suitable for manufacturing, maintenance, warehouses and other places of machinery and equipment. However, it is not suitable for use in environments prone to spontaneous combustion, media full of corrosive gases, and workplaces with relative humidity greater than 85%. It is not suitable for hanging metal transportation. The main parameters of the European hoist gantry crane are as follows:

| Crane Type | MHO European single girder gantry crane |

| Lifting Capacity | 3.2-20t |

| Span | 7.5-31.5m |

| Lifting Height | / |

| Working Class | A5 |

| Ambient Temperature | -25~40℃ |

| Crane Type | MGO European double girder gantry crane |

| Lifting Capacity | 3.2~80t |

| Span | 7.5-31.5m |

| Lifting Height | |

| Working Class | A5, A6 |

| Ambient Temperature | -25~40℃ |

Advantages of European Style Crane

- Optimized European standard design, lightweight

- low load pressure on wheels, compact structure, and

- Excellent running capacity, two-speed lifting, the

- hoist and the whole machine can be controlled by frequency conversion, the

- Stable and maintenance-free operation.

What Are the Advantages of European Standard Cranes Compared With Traditional Cranes?

Due to more advanced design concepts, European single girder cranes are characterized by small size, lightweight, minimized limiting distance from hook to wall and maximized lifting height. Compared with traditional overhead cranes, European single-girder cranes have advantages in the following aspects:

First of all, European cranes can provide a more efficient working space than traditional cranes. In addition, Euro cranes require less working space and can fulfil more functions. Thirdly, due to their lightweight, Eurocranes have much less wheel pressure than conventional cranes. Last but not least, Euro cranes save a lot of money in terms of investment in the construction of the plant, long-term heating costs, air conditioning and other maintenance costs. It can be seen that the European crane is a good choice for your material handling.

European Gantry Crane Features

- Mechanical components

The main girder is partly a railroad box girder or steel girder, and the end girder is made of welded steel (rectangular tube). Between the end girders and the main girder, 10.9 high-strength bolts are used throughout.

Box girders are used for part of the railroad girder or H-beam structure, steel plate welded and formed

Steel plate material is Q235-B (Q345-B optional)

Vertical deflection is L/800

All-steel shot blasting pre-treatment to Sa2.5 grade standard

Steel is carefully inspected and cleaned before welding, usually with automatic welding machines (MIG or semi-automatic welding)

All welds for X-ray non-destructive testing

Rectangular steel tube bundles or welded moulding in a single process moulding by CNC machine, steel plate Q235-B material

Each end girder is equipped with double rims, buffers and derailment protection devices

The maintenance platform (maintenance walkway) of the double girder crane is installed on the drive side of the crane along the direction of the main girder.

The main girder and end girder are connected with 10.9 high-strength bolts to ensure the precise and smooth operation of the whole machine. - Electrical components

Power supply: safety sliding contact wire

With phase sequence protection function

The operation of the hoisting mechanism and crane are controlled separately.

They can run simultaneously or independently.

Specialized vibration control contactor for crane

The control panel is corrosion-resistant and protected to IP55

All plug sockets with heavy-duty plugs, reliable sealing and firm insertion

Components in the control box are well laid out and easy to maintain

Plug connection parts are protected by insulated plastic housings

All cables are labelled with numbers for easy identification

The movement of the trolley is powered by insulated PVC flat cables specially designed for cranes with stress levels up to 450 / 750V.

The trolley’s mobile power system consists of flat cables, galvanized slide rails and small cable clamps for smooth sliding. - Lifting mechanism

See Euro hoist trolley for details. - Running motor

The crane travelling mechanism is in the form of a uniform drive, which is divided into two solutions:

The motor has a soft-start characteristic and can be “soft-started” if it is not connected to a starting resistor and is supplied with power directly without the need for other technical measures. Friction braking with adjustable braking speed. The impact of starting and stopping the crane has been greatly improved, the reduction system adopts closed hardened gears, grinding fine processing, smooth transmission, low noise, high load capacity, low temperature, and long life.

Adopt a three-in-one” (brand: ABM, SEW, SZW) drive system, with superior performance.

- Protection device

The fall protection of the hoist and crane’s 3-in-1 motor prevents accidental falls

Rain cover: for outdoor crane lifting mechanism, electrical cabinet and drive mechanism

Audible and visual alarm devices

Wireless anti-collision device - Operating controls

There are several operating methods for you to choose from for the European Electric Hoist Overhead Crane: ground flashlight door, Remote Control, flashlight door+remote control and so on.

Ground level operation is simple and the crane operator enjoys greater freedom.

Dual stop button or rocker-type joystick.

Customized operation design is available.