What Is a Metallurgical Electric Hoist?

Metallurgical electric hoist introduction is a type of material handling equipment, specially designed for the application in metallurgy environments for handling molten metal, etc. The metallurgical electric hoist is equipped with dual brakes, double spacing, insulation boards, and other protections, with the working class of M3. The lifting capacity of a metallurgical electric hoist is 1 to 20 tons.

The metallurgical electric hoist is designed to meet the lifting requirements of special environments, such as fire and explosion dangerous and corrosive medium environments or areas.

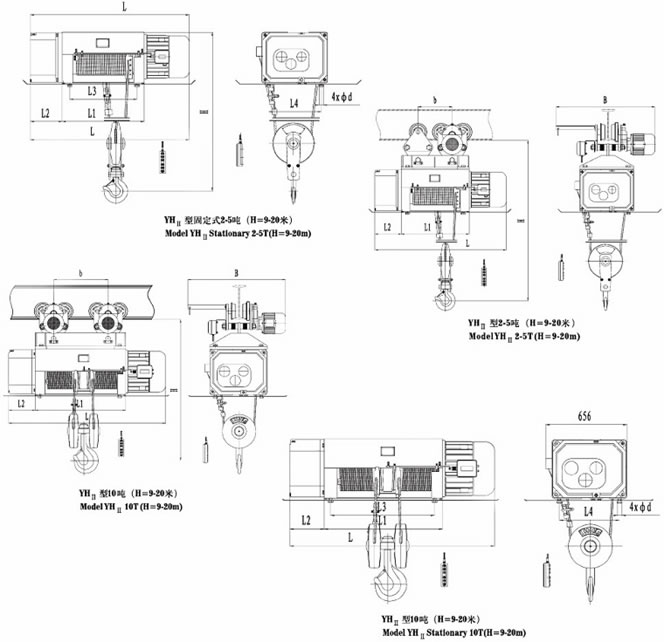

| Crane Type | YH Metallurgical Electric Hoist |

| Lifting Capacity | 1~20t |

| Span | / |

| Lifting Height | 6~18m |

| Working Class | M3 |

| Ambient Temperature | -20~40℃ |

Components of Metallurgical Electric Hoist

Metallurgical electric hoist mainly consisted of a lifting mechanism, travelling mechanism, electrical controlling system, and braking system, with dual brake, and dual spacing, insulation boards and other protection devices, etc.

Features of Metallurgical Electric Hoist

- Double spacing protection.

The metallurgical electric hoist lifting mechanism is equipped with double limit protection, off-the-fire limit protection and off-control limit protection. The former will take into effect when the hook is up to the safety limit and the latter will de-energize the total contacts to protect the hoist.

- Dual brake protection.

Metallurgical electric hoist is operated in dangerous environments so double brakes are equipped to ensure the security of the hoist and people.

- High-temperature protection.

The metallurgical electric hoist can effectively avoid direct heat radiation with insulation protection to keep the wire rope or cable from damage caused by high temperatures. Also, the core wire rope and cable are made of high-temperature resistance steel core.

- Operation mode.

Remote Control and ground control are available to ensure the security of the hoist operator and the hoist.

- Safety devices.

Various safety devices are installed to ensure a metallurgical electric hoist, such as double limit protection, dual brake protection, high-temperature protection, short circuit protection, no-voltage protection, electrical interlock protection and others, etc.

Application of Metallurgical Electric Hoist

A metallurgical electric hoist is used to lift and handle molten metal in metallurgy industries. Also, it can be used in special environments or areas such as fire, explosive, corrosive medium environments, etc.