What is a Warehouse Overhead Crane?

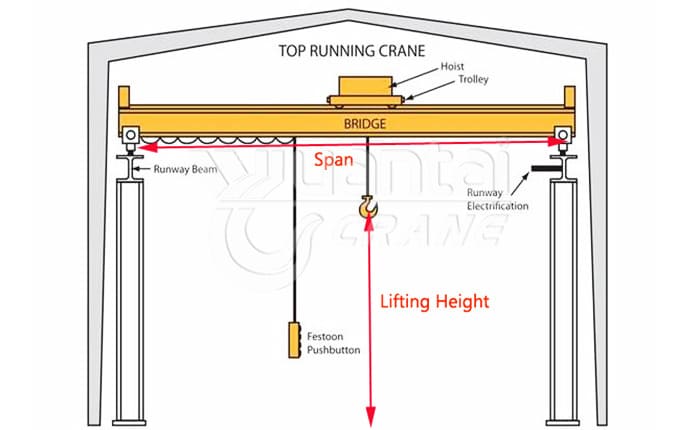

Warehouse overhead cranes are essential equipment for lifting and moving heavy loads in warehouses, factories, workshops, and other industrial settings. A warehouse overhead crane is a type of crane that is mounted on a fixed or movable beam that runs along the ceiling or roof of a warehouse. It consists of a hoist that can lift and lower loads, a trolley that can move the hoist along the beam, and a bridge that connects the beam to the supporting structure. A warehouse overhead crane can span the entire width and length of a warehouse, allowing it to cover a large area and reach any point within it.

Warehouse cranes can improve efficiency, safety, and productivity, as well as save space and reduce labour costs. Warehouse overhead cranes are also known as electric overhead travelling cranes (EOT cranes) or bridge cranes. They are widely used for lifting and transporting materials, equipment, machinery, and finished products in various industries, such as manufacturing, construction, mining, automotive, aerospace, and more.

Types of Warehouse Overhead Cranes

There are different types of warehouse overhead cranes available in the market, depending on their design, function, and application. Some of the most common types are:

- Single girder warehouse overhead crane: This type of crane has one beam that supports the hoist and trolley. It is suitable for light to medium-duty applications, with capacities ranging from 1 to 20 tons and spans up to 30 meters.

- Double girder warehouse overhead crane: This type of crane has two beams that support the hoist and trolley. It is suitable for heavy-duty applications, with capacities ranging from 5 to 500 tons and spans up to 60 meters.

- Top running warehouse overhead crane: This type of crane has a bridge running on top of the rails that are mounted on the supporting structure. It is suitable for high-ceiling warehouses or where there is no obstruction on the floor.

- Underhung warehouse overhead crane: This type of crane has a bridge running under the rails that are mounted on the ceiling or roof. It is suitable for low-ceiling warehouses or where there is an obstruction on the floor.

- Single box girder warehouse overhead crane: This type of crane has a box-shaped beam that provides more rigidity and stability than a single girder crane. It is suitable for medium to heavy-duty applications, with capacities ranging from 5 to 50 tons and spans up to 35 meters.

- Double box girder warehouse overhead crane: This type of crane has two box-shaped beams that provide more rigidity and stability than a double girder crane. It is suitable for very heavy-duty applications, with capacities ranging from 50 to 500 tons and spans up to 60 meters.

Warehouse Bridge Crane Benefits

- They can lift and move loads of up to several hundred tons with ease and precision.

- They can operate at high speeds and with smooth movements, reducing the time and effort required for loading and unloading operations.

- They can utilize the vertical space of a warehouse, freeing up floor space for other purposes.

- They can reduce the risk of accidents and injuries caused by manual handling or by using forklifts or other vehicles.

- They can increase the quality and safety of the products by minimizing damage or contamination during handling.

- They can lower the maintenance and operating costs by using less energy and requiring fewer repairs than other lifting devices.

Warehouse Overhead Crane Features

- Remote Control: This feature allows the operator to control the crane from a distance using a wireless device. It can improve convenience, visibility, and safety for the operator.

- Variable frequency drive (VFD): This feature allows the operator to adjust the speed and acceleration of the crane according to the load and working conditions. It can improve efficiency, accuracy, and energy saving for the crane.

- Load limiter: This feature prevents the crane from lifting loads that exceed its rated capacity. It can protect the crane from overload and damage.

- Anti-sway device: This feature reduces the swinging or oscillation of the load during lifting and moving. It can improve stability, precision, and safety for the crane and the load.

- Anti-collision device: This feature prevents the crane from colliding with other cranes, objects, or people in the same area. It can avoid accidents and injuries for the crane and the surroundings.

- Emergency stop button: This feature allows the operator to stop the crane immediately in case of an emergency. It can prevent further damage or harm to the crane and the load.

How to Choose the Right Warehouse Crane for Your Business?

1. Understand your working conditions needs

- The type and weight of the load you need to lift and move

- The size and layout of your warehouse

- The height and clearance of your warehouse

- The frequency and duration of your lifting operations

- The budget and maintenance costs of your crane

2. Consult with a professional crane manufacturer or supplier who can provide you with expert advice and customized solutions. Compare different types, models, and features of warehouse overhead cranes and select the one that best suits your needs and preferences. Please feel free to contact us for a quotation.

3. Ensure that the crane meets the relevant standards and regulations of your industry and location

Overhead Crane Specifications&Bridge Crane Specifications

- Capacity: The capacity of an overhead crane is the maximum weight that it can lift safely. The capacity is determined by the design and strength of the bridge, trolley, hoist, and other components. The capacity is usually expressed in tons or kilograms. Bridge cranes typically have a lifting capacity in the range of 5 to 550 tons.

- Span: The span of an overhead crane is the distance between the centerlines of the two rails that support the bridge. The span affects the stability and efficiency of the crane operation. The span is usually measured in meters or feet. Bridge cranes typically have spans in the range of 1 meter to 36 meters.

- Lifting height: The lifting height of an overhead crane is the vertical distance from the floor to the highest point that the hoist can reach. The lifting height depends on the length of the hoist rope or chain, the clearance under the bridge, and the height of the hook. The lifting height is usually measured in meters or feet. The height of the bridge cranes is generally customized to the specific needs of the customer.