Recently we received an inquiry from Singapore customer about hoist. At the beginning, customer inquired 7ton electric Wire Rope Hoist, but after we sent the drawing of the wire rope hoist, they thought the size of wire rope hoist is so big. After we talked, finally they chose the 10 ton monorail electric Chain Hoist.

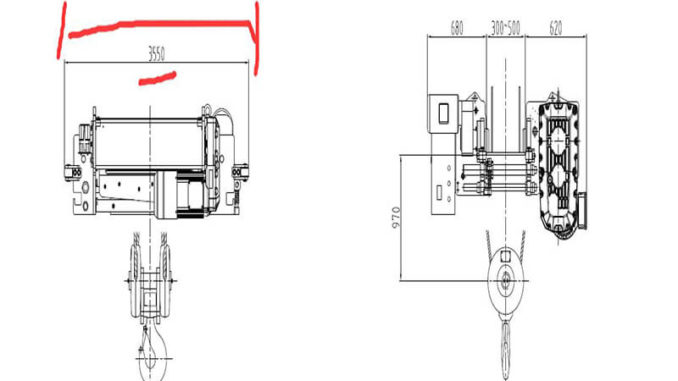

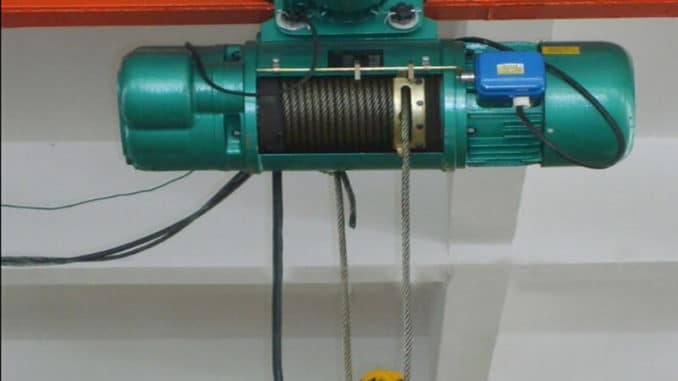

wire rope hoist dwg

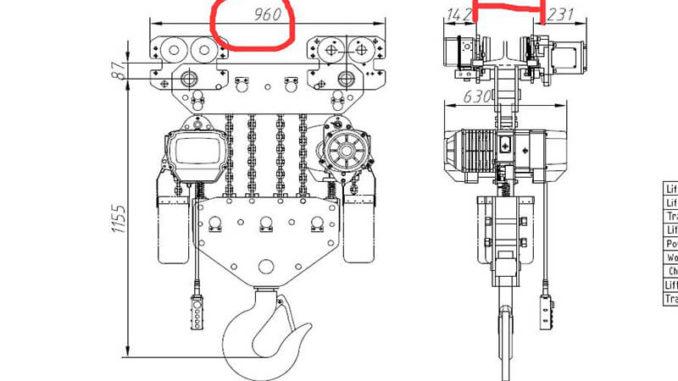

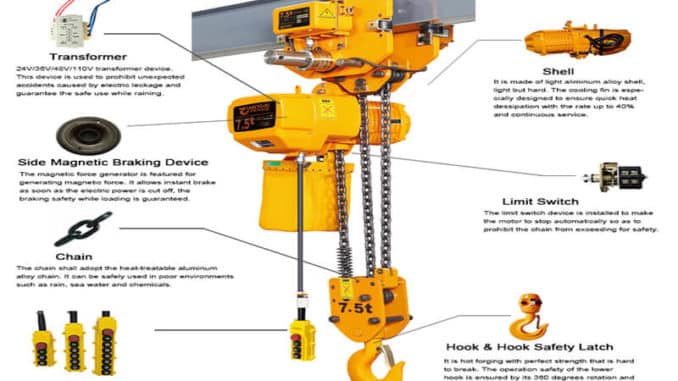

chain hoist drawing

Electric Hoist Project customer choose

Type: Monorail Electric Chain Hoist

Lifting Capacity: 10ton

Lifting Height: 40m

So do you know the differences of electric chain hoist and electric wire rope hoist?

When many customers order electric hoists, the sales staff will ask about the tonnage, lifting height, speed and other parameters. One of them asks whether they want a wire rope or a chain. Many customers do not know the differences.

The difference between electric chain hoist and electric wire rope hoist needs to be analyzed in terms of their volume, running distance, accuracy, transmission power structure, and different lifting heights. Electric wire rope hoists and electric chain hoists are basically the same in structure.

All belong to the electric hoist, which is a kind of lifting equipment that combines lifting and walking. The lifting part consists of three parts.

working environment:

Electric chain hoists are mainly used in major factories, warehouses, wind power generation, logistics, docks, construction and other industries for lifting or loading and unloading goods.

Electric wire rope hoists are mainly used for the installation and movement of various large and medium-sized concrete, steel structures and mechanical equipment. Mechanical equipment for building works.

Motor:

Electric wire rope hoist adopts conical rotor motor motor

The electric chain hoist adopts a cylindrical rotor motor. The braking principle of the side magnetic brake is the same. When the power is on, the brake disc and the end cover are separated. When the power is off, the spring brake makes the brake lock and brake. .

In addition, in the two-speed electric hoist, the wire rope electric hoist uses two hoisting motors, while the chain electric hoist uses the same motor with two sets of windings.

Transmission power structure:

The electric wire rope hoist uses a drum, and the wire rope is wound in the drum groove in an orderly manner through the rope guide.

The electric chain hoist uses a sprocket to guide the chain into the chain belt.

Different volumes:

The picking and winding device of the chain hoist is a chain, the rotation of the sprocket is the key to lifting, and the winding direction of the chain on the sprocket can be set at will, with high flexibility, reasonable structure and small volume.

Wire rope hoist, the winding device is wire rope, and the lifting and lowering is rotated by the reel. To rise to the maximum height, the wire rope needs to be wound on the reel for at least 3 turns. This leads to an increase in the length of the reel, an increase in the height, and an increase in the length of the reel, and the volume of the equipment will increase.

Scope of use:

Electric wire rope hoists are often used in Single Girder Overhead Cranes and Single Girder Gantry Cranes, especially large tonnage cranes above 5t, and wire rope electric hoists have an absolute advantage.

Electric chain hoists are often used in cranes below 5t, especially in assembly lines, wind power projects, cantilever cranes and KBK light and small lifting equipment.

Different service life:

The wire ropes configured by the wire rope hoist are relatively thin. If the equipment is often operated under the conditions of humidity, high temperature, acid and alkali fog, the wire rope is easy to break.

The cross-section of the chain hoist is relatively large, and the core material is generally resistant to high temperature and oxidation, so it will not undergo major changes in harsh environments, so it has a longer life.

Lifting heights vary:

The electric wire rope hoist lifts heavy objects by the elastic deformation of the wire rope wound on the reel. The smaller the diameter of the reel, the greater the variation of the wire rope type, because one side is under pressure and the other side is under tension. This force does not exceed the specification, and the diameter of the reel needs to be increased.

The chain hoist is a chain link hinged, and the chain mainly bears the tensile force. In order to reduce the extrusion strength of the contact surface between the chain rings and between the chain ring and the sprocket socket, the sprocket is made into a socket shape.

It can be seen from this that the diameter of the former reel is larger than the diameter of the latter’s sprocket, so the lifting height of the former is lower than that of the latter for the same height of the track.

The running distance is different:

The axis of the wire rope hoist is parallel to the centerline of its trolley running track.

The chain hoist and the centerline of the running track can be installed at 90 degrees.

Therefore, under the same conditions and track length, the latter has a longer running distance.

The mechanics are different:

During the lifting and lowering process of the electric wire rope hoist, the tension and pressure on both sides are balanced;

The chain hoist of the chain hoist can be set at will when the chain is wound on the sprocket, with high flexibility.

Different resistance to diagonal pull:

The electric chain hoist and the running trolley are hinged. There is a large gap between its lifting hole and the bearing beam of the running trolley, and the former can rotate around the latter. The center line of the chain can be basically kept perpendicular to the axis of the sprocket along the tangential direction of the pitch circle of the sprocket, so it can work normally even if it is inclined;

There is a rigid connection between the wire rope hoist and the running trolley, so when the diagonal pulling force is too large, the wire guide is easily damaged. If the operation is not stopped in time at this time, it may cause click rupture, which will lead to the damage of the entire equipment.

The winding device is different:

The winding device of the wire rope hoist is a wire rope, which is rigid and prone to grooving under no-load conditions. When lifting a small weight or transporting a heavy object to the support, the problem of rope disorder is more likely to occur;

The chain hoist winding device is a chain, because the winding method is hinged, there is no rigidity, and there is no problem of rope disorder.

Any inquiry about hoists, please contact us!