Understanding Crane Structure Designs&Types of Cranes

Crane structure design affects the efficiency, safety and versatility of cranes in various industries. The Yuantai team’s bridge crane design, gantry crane design, jib crane design and hoist design each have their characteristics, making it easy for customers to choose the right crane for different working conditions.

- Main Girder Design: The choice between a single and double girder significantly affects the load-carrying capacity of the crane. The double girder design enhances stability and is suitable for heavier loads.

- End girders: These components support the bridge and house the wheels and motors responsible for the horizontal movement of the crane along the runway.

- Vertical Support Systems: In gantry and jib cranes, vertical supports, whether outriggers or columns, provide stability and ensure the structural integrity of the crane.

- Hoisting structures: The design of the hoisting mechanism, including the reel or chain system, affects the lifting capacity of the crane.

- Material Selection

Choosing the right material is fundamental to the structural design of a crane. High-strength steel alloys are widely used for their excellent load-carrying capacity and durability. Material selection must take into account factors such as corrosion resistance, temperature resistance and the specific requirements of the environment in which it will be used.

Overhead Crane Design

Components of Overhead Crane Structure:

- Bridge Girder: The horizontal beam that spans the width of the crane, providing support for the hoist and trolley.

- End Trucks: Attached to the bridge girder, these house the wheels and motor that allow horizontal movement along the runway.

- Hoist: The lifting mechanism that raises and lowers the load. It consists of a drum, wire rope, and a hook or other attachment.

- Runway: The track on which the crane travels horizontally, allowing it to cover a large working area.

Overhead Crane Design Considerations:

- Load Capacity: Overhead crane design starts with determining the maximum load the crane will handle. This factor influences the size and specifications of various components.

- Span: The distance between the runway rails is a critical design consideration, impacting the crane’s coverage area.

- Lift Height: The vertical distance the crane needs to lift the load influences the length of the wire rope and the hoist specifications.

Overhead Crane Applications:

Overhead cranes find applications in manufacturing, warehouses, and material yards. Their ability to lift heavy loads and move them horizontally makes them ideal for tasks requiring precision and efficiency.

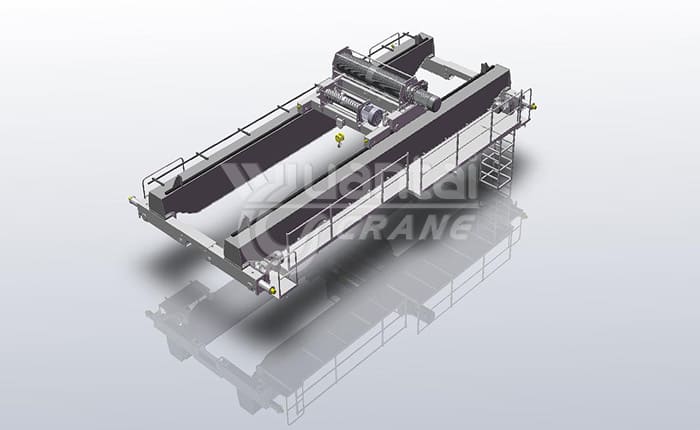

Gantry Crane Design

- Single Girder Gantry Cranes: have a single main girder support, making them suitable for light to medium loads.

- Double Girder Gantry Crane: utilizes two main girders to increase stability, making it suitable for heavier loads.

Components of Gantry Crane Structure:

- Girder: A horizontal beam that provides support and carries the load.

- Legs: Vertical supports that connect the girder to the ground, forming an A-frame or box structure.

- End Brackets: Fitted with wheels and motors to allow horizontal movement along the gantry runway.

- Hoist: Similar to an overhead crane, a gantry crane uses a lifting mechanism to raise and lower the load.

Gantry Crane Design Considerations:

- Load type: The nature and weight of the load determine whether a Single Girder Gantry Crane or a Double Girder Gantry Crane is more appropriate.

- Span and Height: Similar to overhead cranes, the span and lifting height influence the overall design and specifications.

- Mobility: Gantry cranes offer mobility advantages and are suitable for outdoor applications such as construction sites and shipyards.

Gantry Crane Applications:

Gantry cranes are widely used in shipyards, construction sites and outdoor yards. Their mobility and versatility make them an integral part of lifting and transporting heavy loads in a variety of environments.

Jib Crane Design

Components of Jib Crane Structure:

- Jib Arm: The horizontal boom that extends from the crane’s vertical support, offering a range of motion.

- Vertical Support: Either freestanding or attached to a wall, this provides stability and supports the jib arm.

- Hoist: Similar to other crane types, the hoist is responsible for lifting and lowering loads.

Jib Crane Design Considerations:

- Rotation Range: Depending on the application, the crane’s rotation range can be fixed or a full 360 degrees.

- Reach: The length of the jib arm determines the crane’s coverage area, influencing its suitability for specific tasks.

- Mounting Type: Free-standing jib cranes offer more flexibility in terms of rotation, while wall-mounted cranes are more space-efficient.

Jib Crane Applications:

Jib cranes are often found in workshops, manufacturing facilities, and assembly lines. Their compact design and ability to provide localized lifting make them ideal for tasks that require precision and agility.

Electric Hoist Design

- Electric Chain Hoist: Uses an electric motor to power a chain mechanism for lifting.

- Wire Rope Hoist: Utilizes a drum wound with wire rope for lifting heavier loads.

- Manual Hoist: Operated by hand, suitable for lighter loads and manual material handling.

Components of Hoist Structure:

- Motor: The power source that drives the lifting mechanism.

- Gear Train: Transfers power from the motor to the drum or chain mechanism.

- Brake System: Ensures controlled stopping and holding of the load.

- Control System: Allows the operator to regulate lifting and lowering.

Hoist Design Considerations:

- Load Capacity: The hoist’s load capacity must align with the requirements of the crane it is part of.

- Lift Speed: Different applications may require varying lift speeds, influencing the design of the hoist.

- Duty Cycle: The frequency and duration of use impact the hoist’s design to ensure durability and reliability.

Hoist Applications:

Hoists are integral components of various cranes, contributing to their lifting capabilities. The type of hoist selected depends on the specific requirements of the material handling task.